BOPET film coating is a widely recognized material in various industries, renowned for its unique properties and versatility. This polyester-based film is produced through the biaxial orientation of polyethylene terephthalate (PET). The resulting film is not only strong and durable but also offers excellent clarity and thermal stability, making it a popular choice for a multitude of applications. Understanding the properties and benefits of BOPET film coating can help businesses leverage its capabilities effectively across different sectors.

Properties and Benefits of BOPET Film Coating

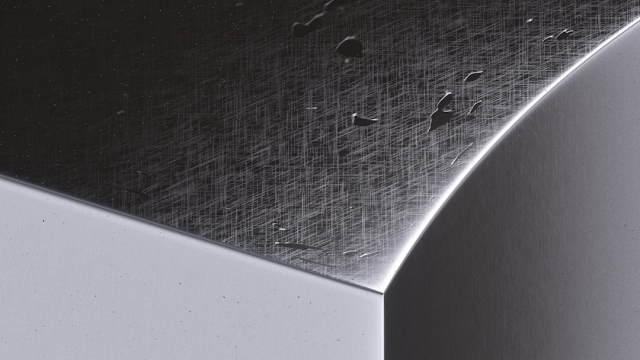

BOPET film coating boasts several remarkable properties that contribute to its widespread adoption. One of the primary characteristics is its high tensile strength, which ensures that the film can withstand significant stress without tearing. Additionally, BOPET film exhibits low moisture absorption, making it resistant to environmental factors that could compromise its integrity. Another advantage of BOPET film is its excellent barrier properties. It effectively protects against gases, moisture, and light, which is crucial for preserving the quality of packaged goods. The film’s optical clarity is also noteworthy, allowing for vibrant printing and visibility of the product inside. Furthermore, BOPET film is chemically resistant, which enhances its longevity and performance in demanding applications. In terms of benefits, the use of BOPET film coating can lead to reduced material costs due to its lightweight nature, while still providing robust protection. Its versatility allows it to be used in various forms, including pouches, labels, and wraps, making it an ideal choice for businesses looking to optimize their packaging solutions.

Applications of BOPET Film Coating in Various Industries

BOPET film coating finds applications across an array of industries, showcasing its adaptability and performance. 1. Packaging: In the food and beverage industry, BOPET film is commonly used for packaging snacks, confectionery, and other perishable items. Its barrier properties help maintain freshness and extend shelf life, which is essential for consumer satisfaction. 2. Electronics: BOPET film is also utilized in the electronics sector, particularly in the production of capacitors and displays. Its electrical insulation properties make it suitable for these applications, providing reliability and efficiency. 3. Textiles: In the textile industry, BOPET film coating is used to enhance the durability and appearance of fabrics. It can be applied as a protective layer, improving resistance to water, stains, and UV light. 4. Graphic Arts: The film’s excellent printability allows it to be used for high-quality graphics and labels, making it a favorite among companies looking for aesthetic appeal in their branding and marketing materials. 5. Solar Energy: BOPET film is increasingly being used in the production of solar panels, where its optical properties help improve the efficiency of energy capture.

Leading Suppliers and Manufacturers of BOPET Film Coating

When considering BOPET film coating for various applications, working with reputable suppliers and manufacturers is crucial. These companies specialize in producing high-quality BOPET films that meet industry standards. Here is a list of some notable suppliers:

| Supplier | Specialization | Website |

|---|---|---|

| DPG PET | BOPET Film Products | dpgpet.com |

| DuPont | Advanced Materials | dupon.com |

| BOPET Film Co. | Custom Film Solutions | bopetfilmco.com |

| Toray Plastics | Packaging Solutions | toray.com |

In conclusion, BOPET film coating offers a wide range of properties and benefits that make it a valuable material in various industries. Its durability, barrier properties, and adaptability to different applications ensure that it remains a preferred choice for businesses looking to enhance their products and packaging solutions. By partnering with leading suppliers and manufacturers, companies can effectively utilize BOPET film to meet their specific needs and achieve optimal performance in their operations.